Fixtures

Exploring Recto’s In-house Tool Room: Fixtures & Repair

Fixtures

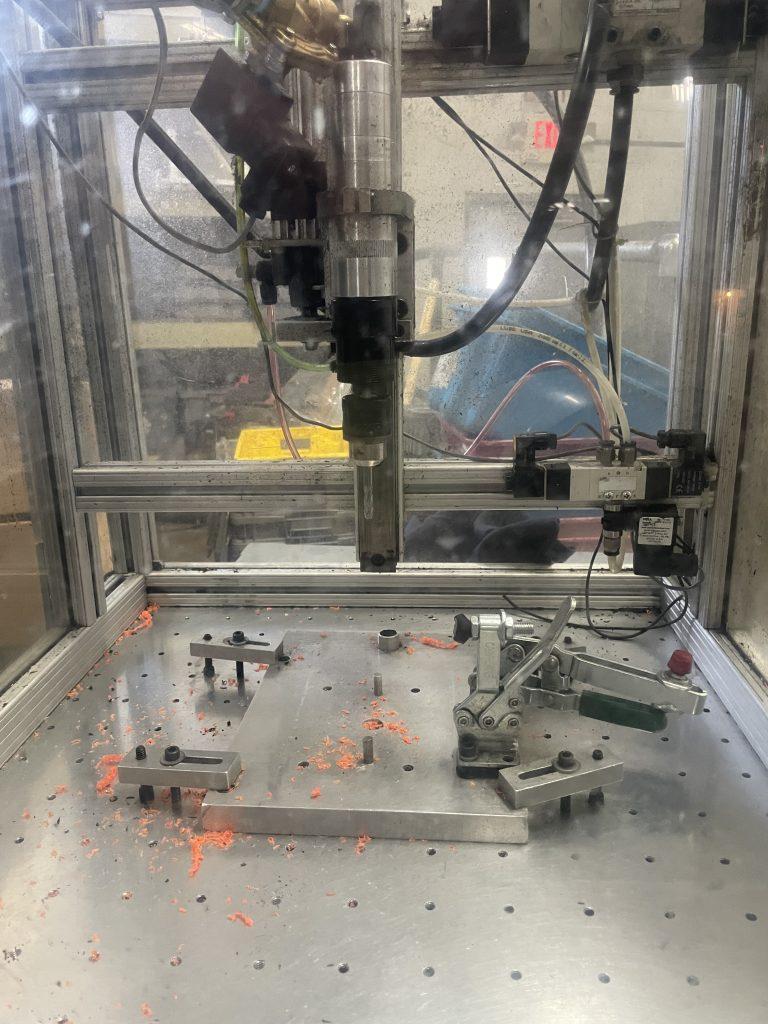

Another important function of our Tool Room is the design and manufacturing of custom fixtures. These custom fixtures are made in-house to support our secondary machining, rotary/indexing tables and end-of-arm operations, ensuring that they proceed with accuracy, repeatability and increased productivity.

All fixtures are unique to the process. Fixtures used in secondary machining hold molded parts firmly in place, allowing the surface of the part to be cut to final critical tolerances or to add threads to molded in holes, for example. Those used on rotary or indexing tables can be used to retain components to be assembled at the molding press while the end of arm fixtures are attached to robots, which can perform numerous functions. These same fixtures are used in general automation away from the press.

Repair & Maintenance

Our Tool Room isn’t just for designing and building new tooling and fixtures. We also have a wide range of equipment for maintaining, revising and repairing our existing molds.

All injection molds go through everyday wear. To ensure that they maintain high levels of precision over time, these tools require maintenance. Cleaning, minor steel repairs and lubrication are ongoing tasks in the toolroom. Occasionally, molds experience more serious damage, which our team can then repair, restoring the molds back to their original state.

Our tool room equipment includes:

- Haas VF-2 vertical mill

- Hurco Vertical mill

- Various Bridgeports

- 2 Lathes

- 5 Surface grinders

- Roll-in band saw

- Sodick wire EDM

- Sodick CNC ram EDM

- Laser welder

- MIG/TIG welders

- Horizontal mill

- Charmilles Hole-Popper

We also have a range of inspection equipment to ensure that the job is finished and the molds are back up to standard.

Ready to get started?

Since 1919, Recto Molded Products has been an innovative leader in molded plastic components and assemblies. We are known for our versatility and our wide range of capabilities, as well as our extensive knowledge of injection molding and related operations. To learn more about what we can do for you, or if you’re ready to request a quote, don’t hesitate to contact us today.