Services

Recto Molded Products is positioned to offer a variety of services to meet your injection molding needs. We have a robust tool room for maintenance of our equipment and tooling, as well as a design and engineering team to help you determine the best possible design for your next molded plastic product. Our facility is also well equipped to perform secondary finishing operations, product assembly, and final packaging and shipping as well, eliminating the need to outsource different operations to multiple suppliers. We offer all of this under one roof.

Our Operations

Design & Engineering

Our engineering support is available at all stages of product development, from rapid prototyping and testing to production tooling and final assembly.

Injection Molding

Our injection molding equipment runs three-shift production, five days a week. Currently, our presses range from 55 to 500 tons and many feature robotic integration for improved efficiency through automation.

Automation

Automation has been integrated throughout our facility resulting in customer cost savings through the reduction in labor, lead times, and improved efficiency of our systems.

Tooling

Recto maintains a well-equipped tool room for maintenance, tool building, and production solutions, optimizing our efficiency and ensuring the quality of our injection molding processes.

Secondary Operations

We perform a wide range of secondary and finishing operations, from CNC machining to ultrasonic welding, to various types of printing.

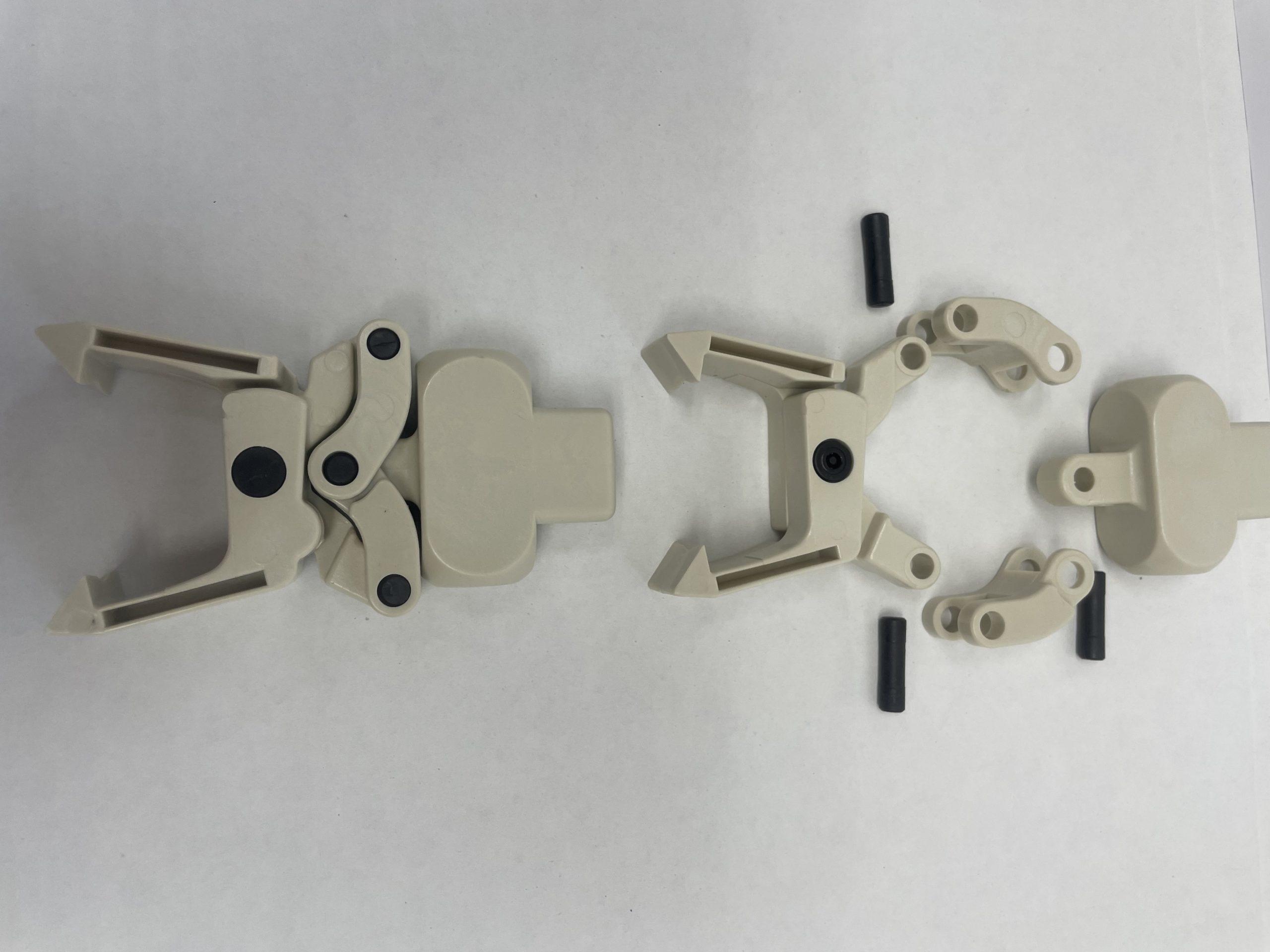

Assembly

While some assembly steps are able to be performed cost effectively at the molding press, more involved assembly procedures take place in our Finishing Department. Product assembly has been a core expertise of Recto for over 75 years, including automobile rectifiers at the company’s inception, bulk photography film loaders for many years afterwards, and today, complete packaged products and various complicated mechanical components.

It is common for one assembled item to include up to 15 components or more, plus additional secondary operations as well. One key to our success in this area has been working to understand, not only each assembly’s requirements, but also as much knowledge as reasonable of its operational functions, interactions, and environment to help aid in developing best methods for assembly and testing. This extra effort has often helped avoid functional complications in the past, as well as allowed for additional inspection/testing steps to be incorporated. If so specified, 100% testing is a service we regularly perform, including form, fit/function.

Packaging & Shipping

Recto offers packaging and shipping services from standardized packaging and labeling to custom packaging, labeling, and shipping options that your project may require.

Ready to get started?

For over a century, Recto Molded Products has offered plastic molded products to a wide range of applications, expanding throughout the decades to improve our machine and molding technology, process control, automation, tooling design, and engineering support at all levels of part development and production. To request a quote, or learn more about how we can serve you, contact Recto today.